PRODUCT CENTER

International standard scale technology, research and development according to your demand.

|

Inconel 625LCF(UNS N06626 W.Nr. 2.4856)

Collect

商品说明

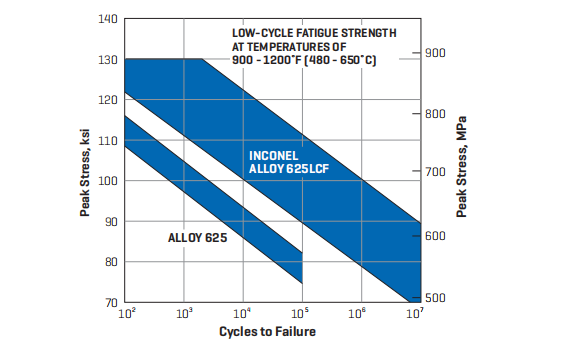

Inconel 625LCF(UNS N06626 W.Nr. 2.4856)1.Inconel 625LCF INTRODUCTION A nickel-chromium-molybdenum alloy that was developed as a fatigue-resistant bellows-quality version of INCONEL alloy 625. Alloying, melting and processing of this alloy are specially designed and controlled to provide a sheet product with optimum resistance to low-cycle and thermal fatigue at temperatures up to 1200°F (650°C). Used in Aircraft exhaust and automotive flexible coupling bellows and expansion joints in various types of process or transport piping 2.Inconel 625LCF STANDARD PRODUCT FORMS Sheet and strip. 3.Inconel 625LCF MAJOR SPECIFICATIONS UNS N06625, N06626 ASTM B 443 ASME SB-443 SAE AMS 5879 4.Inconel 625LCF LIMITING CHEMICAL COMPOSITION, % Ni..........58.0 min. Cr .....20.0 – 23.0 Mo...... 8.0 – 10.0 Nba...3.15 – 4.15 Plus Co. Fe.......... 5.0 max. C..........0.03 max. Si.........0.15 max. N..........0.02 max. Mn.......0.50 max. S....... 0.015 max. Al .........0.40 max. Ti .........0.40 max. P....... 0.015 max. Co.......... 1.0 max. 5.Inconel 625LCF PHYSICAL CONSTANTS AND THERMAL PROPERTIES Density, Ib/in3 ........................................................................0.305 g/cm3 ......................................................................... 8.44 Melting Range, °F ...................................................2350 – 2460 °C ...................................................1290 – 1350 Specific Heat, Btu/lb•°F.....................................................0.098 J/kg•°C........................................................... 410 Curie Temperature, °F........................................................<-320 °C .......................................................<-196 Permeability at 200 Oersted (15.9 kA/m)................. 1.0006 Coefficient of Expansion, 70 – 200°F, 10-6 in/in •°F........ 7.1 20 – 100°C, μm/m •°C ......... 12.8 Thermal Conductivity, Btu • in/ft2•h•°F..............................68 W/m •°C.............................................9.7 Electrical Resistivity, ohm • circ mil/ft............................... 776 μΩ•m................................................ 1.29 6.Inconel 625LCF TYPICAL MECHANICAL PROPERTIES (Annealed) Tensile Strength, ksi............................................................... 130 MPa............................................................ 894 Yield Strength (0.2% Offset), ksi...........................................68 MPa..................................... 469 Elongation, % ..............................................................................50

|