PRODUCT CENTER

International standard scale technology, research and development according to your demand.

|

Hastelloy G-3(UNS N06985 W.Nr. 2.4619)

Collect

商品说明

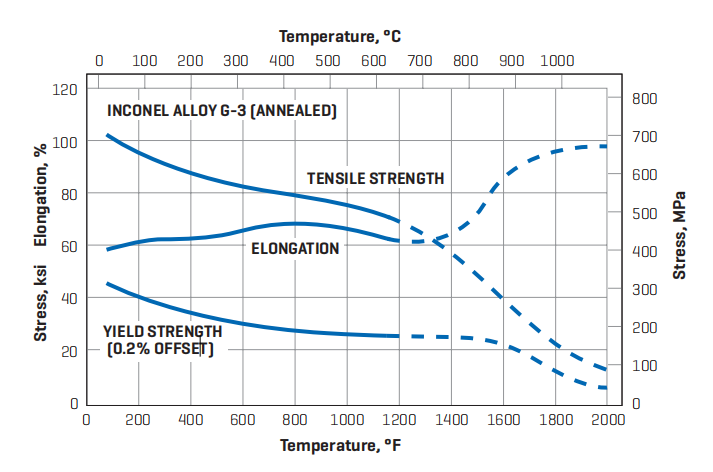

Hastelloy G-3(UNS N06985 W.Nr. 2.4619)1.Hastelloy G-3 Introduction A nickel-chromium-iron alloy with additions of molybdenum and copper. It has good weldability and resistance to intergranular corrosion in the welded condition. The low carbon content helps prevent sensitization and consequent intergranular corrosion of weld heat-affected zones. Used for flue-gas scrubbers and for handling phosphoric and sulfuric acids. 2.Hastelloy G-3 STANDARD PRODUCT FORMS Pipe and tube. 3.Hastelloy G-3 MAJOR SPECIFICATIONS UNS N06985 ASTM B 366, B 581, B 582, B 619, B 622, B 626, B 751, B 775, B 829 NACE MR-0175/ISO 15156 ASME SB-366, SB-581, SB-582, SB-619, SB-622, SB-626, SB-751, SB-775, SB-829 DIN 17744, 17750 – 17752 Werkstoff Nr. 2.4619 ISO 6207, 6208, 9724 4.Hastelloy G-3 LIMITING CHEMICAL COMPOSITION, % Ni.......Remainder Cr......21.0 – 23.5 Fe.....18.0 – 21.0 Mo.........6.0 – 8.0 Cu..........1.5 – 2.5 Nb.......0.50 max. C....... 0.015 max. W........... 1.5 max. Si........... 1.0 max. Plus Co. Mn......... 1.0 max. P..........0.04 max. S..........0.03 max. Co.......... 5.0 max. 4.Hastelloy G-3 PHYSICAL CONSTANTS AND THERMAL PROPERTIES Density, Ib/in3 .........................................................................0.294 g/cm3 ......................................................................... 8.14 Melting Point, °F.....................................................2300 – 2450 °C.....................................................1260 – 1340 Specific Heat, Btu/lb •°F....................................................0.108 J/kg •°C.......................................................... 452 Coefficient of Expansion, 70 – 200°F, 10-6 in/in •°F........8.1 24 – 100°C, μm/m •°C......... 14.6 Thermal Conductivity, Btu • in/ft2• h•°F..............................69 W/m•°C.......................................... 10.0 5.Hastelloy G-3 TYPICAL MECHANICAL PROPERTIES (Annealed) Tensile Strength, ksi............................................................... 100 MPa............................................................ 690 Yield Strength (0.2% Offset), ksi...........................................47 MPa..................................... 320 Elongation, % ..............................................................................50

|