PRODUCT CENTER

International standard scale technology, research and development according to your demand.

|

Hastelloy C22(USN N06022 W.Nr. 2.4602)

Collect

商品说明

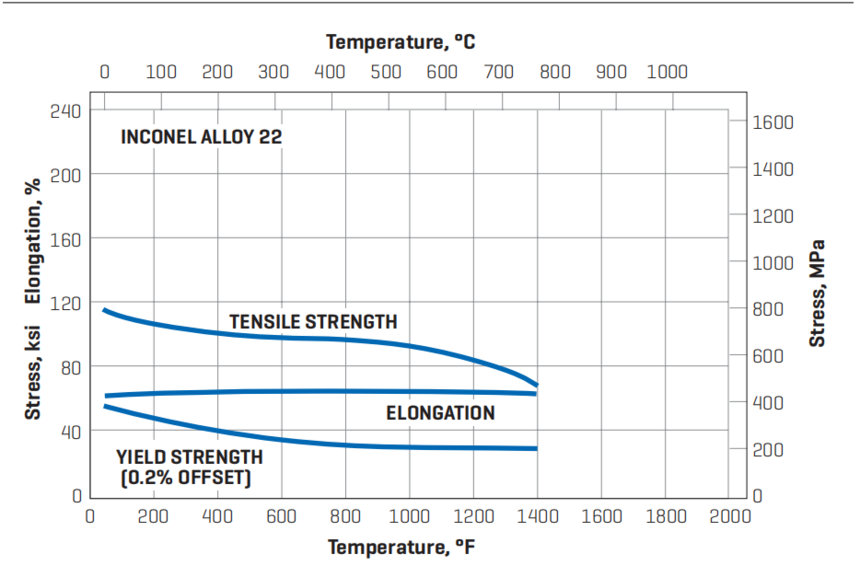

Hastelloy C22(USN N06022 W.Nr. 2.4602)1.Hastelloy C22 Introduction By virtue of its contents of chromium, molybdenum, tungsten and controlled iron, this alloy exhibits excellent resistance to both oxidizing and reducing acid environments, as well as those containing mixed acids. It is particularly useful for resistance to pitting and crevice corrosion in acid-halide environments. Applications include the chemical processing, pollution control, flue gas desulfurization, waste incineration and pulp and paper processing industries. 2.Hastelloy C22 STANDARD PRODUCT FORMS Sheet, strip, plate, round bar, flat bar, forging stock, hexagon and wire. 3.Hastelloy C22 MAJOR SPECIFICATIONS USN N06022 ASTM B 366, B 462, B 564, B 574, B 575, B 619, B 622, B 626, B 751, B 775, B 829, B 906 ASME SB-366, SB-564, SB-574, SB-575, SB-619, SB-622, SB-626, SB-751, SB-775, SB-829, SB-906 ASME Code Cases 2226, N-621 Werkstoff Nr. 2.4602 ISO 6207, 6208, 9723, 9724 DIN 17744, 17750-17754 4.Hastelloy C22 LIMITING CHEMICAL COMPOSITION, % Ni.......Remainder Cr .....20.0 – 22.5 Mo....12.5 – 14.5 Fe..........2.0 – 6.0 W...........2.5 – 3.5 Co.......... 2.5 max. C....... 0.015 max. Mn.......0.50 max. V..........0.35 max. S..........0.02 max. Si.........0.08 max. P..........0.02 max 5.Hastelloy C22 PHYSICAL CONSTANTS AND THERMAL PROPERTIES Density, Ib/in3 (g/cm3)...........................................0.311 (8.61) Melting Range, °F (°C).............2464 – 2529 (1351 – 1387) Specific Heat, Btu/lb•°F (J/kg•°C)......................0.091 (381) Curie Temperature, °F (°C)................................ <-320 (-196) Permeability at 200 Oersted (15.9 kA/m)................. <1.001 Coefficient of Expansion, 10-6 in/in•°F (μm/m•°C) 70-200°F (21–93°C)..................6.90 (12.42) 70-1000°F (21–538°C)............. 7.46 (13.43) 70-1800°F (21–982°C)............. 7.84 (14.11) Thermal ConductivityA , Btu•in/ft2•h•°F (W/m•°C).......91 (13.2) Electrical ResistivityA , ohm•circ mil/ft (μΩ•m)...730.7 (1.215) Young’s ModulusA , 106 psi (GPa)............................ 30.3 (209) Shear’s ModulusA , 106 psi (GPa)........................... 11.0 (75.8) Poisson’s RatioA...................................................................... 0.30 HardnessA , HRB ..........................................................................86 Room temperature, as aged. 6.Hastelloy C22 TYPICAL MECHANICAL PROPERTIES

7.Hastelloy C22 Metallographic structure Hastelloy C22 has a face-centered cubic lattice structure. 8.Hastelloy C22 Corrosion resistance Hastelloy C22 alloy is suitable for various chemical process industries containing oxidizing and reducing media. The higher molybdenum and chromium contents make the alloy resistant to chloride ions, and the tungsten element further improves its corrosion resistance. Hastelloy C22 is one of only a few materials resistant to corrosion in wet chlorine, hypochlorite, and chlorine dioxide solutions. copper chloride). 9.Hastelloy C22 Application area Hastelloy C22 alloy is widely used in chemical and petrochemical fields, such as components and catalytic systems in contact with chloride-containing organics. This material is especially suitable for use in high temperature, inorganic and organic acids mixed with impurities (such as formic acid and acetic acid), and seawater corrosive environments. 10.Hastelloy C22 Other application areas 1. Acetic acid/acetic anhydride 2. Pickling 3. Cellophane manufacturing 4. Chlorination system 5. Complex Mixed Acids 6. Rollers of electro-galvanizing tank 7. Expansion bellows 8. Flue gas cleaning system 9. Geothermal Wells 10. Hydrogen fluoride furnace cleaner 11. Incineration cleaner system 12. Nuclear fuel regeneration 13. Insecticide production 14. Phosphoric acid production 15. Pickling system 16. Plate heat exchanger 17. Selective Filtration System 18. Sulfur dioxide cooling tower 19. Sulfonation system 20. Tube heat exchanger 21. Surfacing valve |